Rapid Prototyping

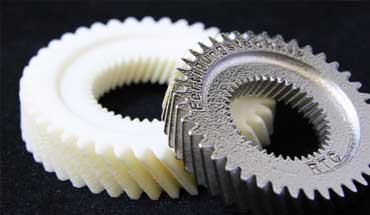

Rapid Prototype(RP) is a physical part that reflects the design intention. One or several samples been made according to the CAD drawing to check the rationality of appearance or structure.

For fast prototyping, we use our manufacturing facility in India under Make in India plant. Try us for your next proto or production run with us.

Usually, the first step is to check the feasibility of a newly developed or designed product, which relies on prototypes in the process as it can identify flaws or abnormal efficiently. deficiencies and disadvantages of the designed product which can help improving the product defects at the point. A small trail production is usually done for improving flaws in the batch as the newly designed products normally come with issues. It will also cause a great deal of loss in material resources and time if to put into production directly. Thus, the prototype literally is just few samples and the process is labor saving, material saving, and time saving. By it’s appearance and testing the prototype, we can quickly find out the insufficient of product design and can improve it, so as to provide sufficient basis for mass production.

About Rapid Prototyping

Usually, the first step is to check the feasibility of a newly developed or designed product, which relies on prototypes in the process as it can identify flaws or abnormals efficiently. deficiencies and disadvantages of the designed product which can help improving the product defects at the point. A small trail production is usually done for improving flaws in the batch as the newly designed products normally come with issues.It will also cause a great deal of loss in material resources and time if to put into production directly.Thus, the prototype literally is just few samples and the process is labor saving, material saving, and time saving. By it’s appearance and testing the prototype, we can quickly find out the insufficient of product design and can improve it, so as to provide sufficient basis for mass production.

Our factory is not only equipped with a variety of manufacturing and processing equipment, but also has a group of professional manual craftsman with years of practical experience. We specialized in making difficult, flexible and creative product models that cannot be completed by machining, and can quickly complete samples according to customers’ needs, which saves a lot of your time.

Why use prototypes?

- In prototyping industry, a prototype will be made to test if the size, appearance and structure etc, is reasonable, after the CAD drawing for the new product design completed.

- From which we can find out the deficiencies of a product design, and then to modify it appropriately.

- Prototype is a combined process that integrates various processing methods to produce samples that meet our requirements.

What are the uses of prototypes?

Prototypes can improve the work efficiency in the R & D department, reduce the risk of product development cost, time. It also helps the verification in some structural performance in the R & D process.

Our advantages

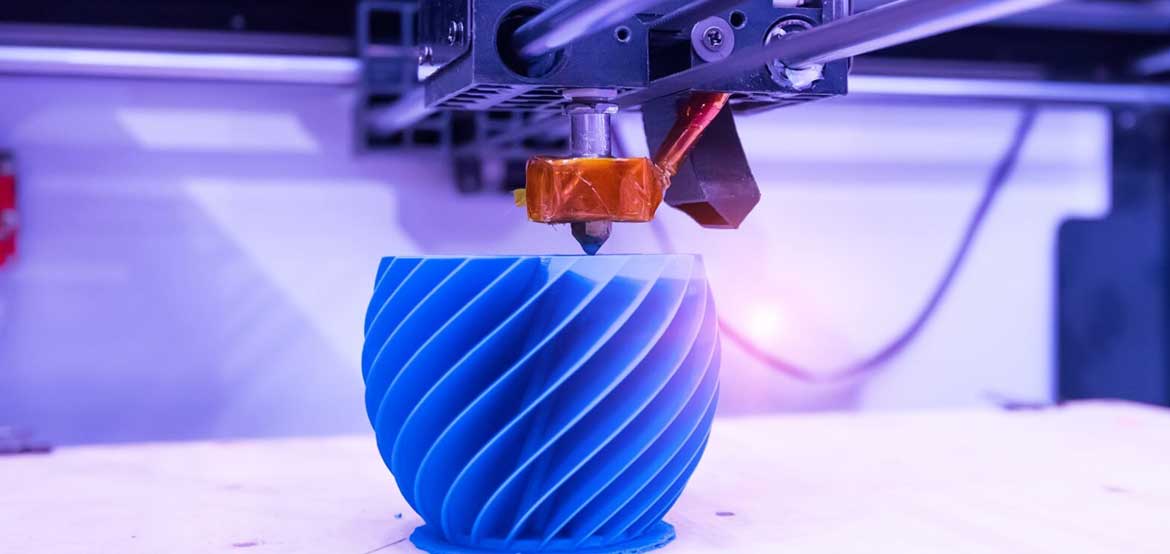

- Dozens of prototyping manufacturing methods, including 3D printing, CNC machining, Vacuum Casting(Urethane Casting), RIM, etc.

- More than 10 years’ experience in prototype industry

- Capable of making all kinds of high-precision, difficult and particularly complex prototypes.

- Offer free evaluation for the future mass production possibilities.

- Able to run each project at low cost.

- No material restrictions.

About Rapid Prototyping

One stop service to meet your low volume production needs.

Idea To Markets is also committed to small batch manufacturing. The number of products in most industries can reach hundreds to thousands or even tens of thousands of pieces. The services ranges from prototype stage to low volume manufacturing till the final formal mass production.

Idea To Markets is also committed to small batch manufacturing. The number of products in most industries can reach hundreds to thousands or even tens of thousands of pieces. The services ranges from prototype stage to low volume manufacturing till the final formal mass production.